Pulse jet engines, a type of valveless engine in which fuel is injected into a tube before being ignited by a series of pulses, have been around for over a century, but they tend to emit a lower specific impulse. As a result, these lightweight propulsion systems can be applied to components that rarely move or are static, making them easy to maintain, but their low efficiency continues to limit their potential for application in vehicle thrust.

31 August 2022 To address this issue, foreign YouTube blogger Integza has used 3D printing to develop a valveless engine capable of continuous ignition. Using this technology, the blogger built his own pulse jet featuring a combustion chamber with printed fuel and oxygen inlet valves, and on the basis of this prototype he has come up with an upgraded version of the metal machine, which can reach ten pulses per second.Integza says that this engine is not the fastest he has ever built, but with better valves it should do even better. Speaking of future plans, the YouTuber added that if he could find a way to do it, he would build an engine that uses a continuous flow of bursts, which would generate insane amounts of thrust. With this in mind, Integza revealed that he is now working on a rotary piloted burst engine that could produce greater efficiency and thrust.

How does a detonation engine work?

Essentially, a pulse detonation engine works by injecting oxygen and propellant into long tubes that are open at one end and closed at the other. Once these tubes are filled, their filling is ignited, causing the fuel to burn and rapidly transition to an explosion. The pressure of this shockwave can travel at speeds of up to Mach 10, pushing the exhaust out of the pipe outlet and generating thrust.

A major advantage of pulse jet engines is that they can lift fuel and oxidiser at high enough pressure to function without the need for a turbopump. In contrast, typical rocket engines rely on complex, expensive turbopumps to push fuel and oxidiser into a chamber at a pressure high enough to prevent it from being blown back out. However, as Integza found, pulse jets can also be very noisy, making them unsuitable for powering manned flight, and less energy efficient than internal combustion engines. As a result, such propulsion systems are more commonly used for thermal energy conversion or to power light radio-controlled aircraft, rather than for providing jet thrust.

△Prototype of the initial engine with 3D printed chambers developed by Integza. Photo from Integza

Integza's 3D-printed prototype

As Integza explains in his video, the pulse jet engine features a clever geometry that creates a cycle of air self-priming, mixing with the fuel and being ignited again, but this does not allow for sustained thrust. To generate more power, this blogger thought it best to use burst assist on this type of engine, and he tested this theory using the Prusa SL1S 3D printer.

Using this printing system and Siraya Tech resin, Integza initially 3D printed a combustion chamber attached to a long acrylic tube as well as air and fuel valves. He said that an Arduino controller could operate the high pressure generator to be ignited, but wasn't sure if this setup would produce a burst. So, to give his engine more power, Integza resorted to injecting pure oxygen into it.

This enabled him to achieve an output of 80 metres per second, enough to punch a hole in a piece of paper and cause a balloon to explode. Not content with this level of thrust, however, the YouTuber went a step further and machined another prototype out of metal, which he says is capable of producing a pure and consistent blast of impact while achieving a speed of 10 pulses per second. When placed in orbit, the engine also proved capable of propelling a platform forward, so Integza describes his prototype as "a good way to explore blast drives". Nevertheless, Integza also felt that his design was flawed by the use of pulsed flows, so he is now developing a rotary detonation engine which allows one or more detonation points to travel continuously in a circular path. The larger power output of these engines makes them more suitable for vehicle propulsion than traditional pulse-based alternatives, and the YouTuber has now committed to making his own engine in his next video. In the meantime, Integza has made the 3D model design files of his prototype jet engine available for free download, enabling those brave enough to try 3D printing one at home.

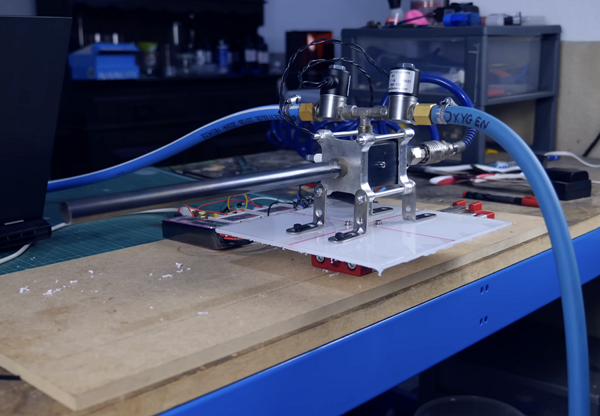

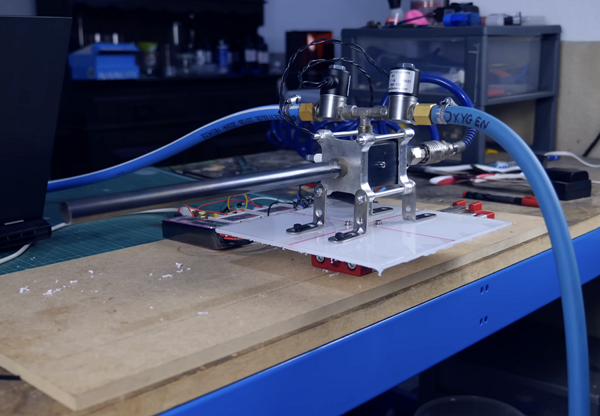

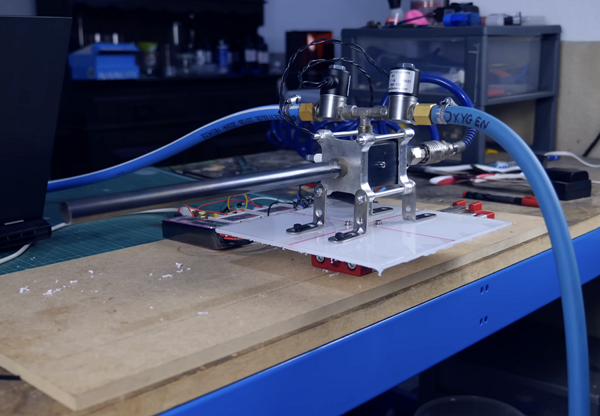

△Integza's metal prototype mounted on a platform on the track during testing. Photo from Integza.

Content creators like Integza provide an accessible way for creators everywhere to learn more about 3D printing and how the technology can be deployed in innovative and exciting ways. in August 2021, Integza developed a 3D printing engine of its own, inspired by Nazi designs and powered by volatile chemical reactions rather than ordinary fuel.

More recently, YouTube blogger AkakiKuumeri also developed a 3D-printed PS5 controller adapter that allows users to play games with one hand. The content creator is now developing a library of 3D printed parts for the game controller, which caters for non-standard hand positions to make playing video games easier.