Makrforged announces the release of Simulation, a simulation testing tool that allows users to simulate part strength before generating optimal print parameters to accelerate the printing process for composite 3D printing

November 15, 2022 - Makrforged announced the release of Simulation, a simulation testing tool that allows users to accelerate the printing process for composite 3D printing by simulating part strength prior to generating optimal print parameters. While Markforged (NYSE: MKFG ) is known for its continuous carbon fiber (CCF) and metal extrusion 3D printers, it has also been developing excellent software. makrforged initially launched its print management tool, Eiger, in 2019, followed by the Digital Forge software portfolio in 2021 .

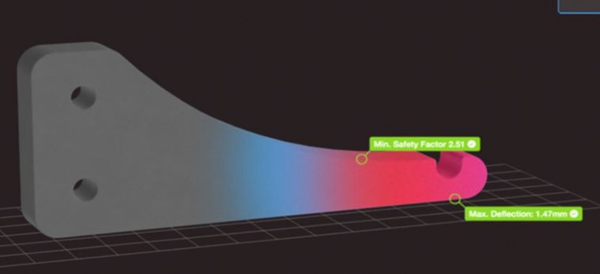

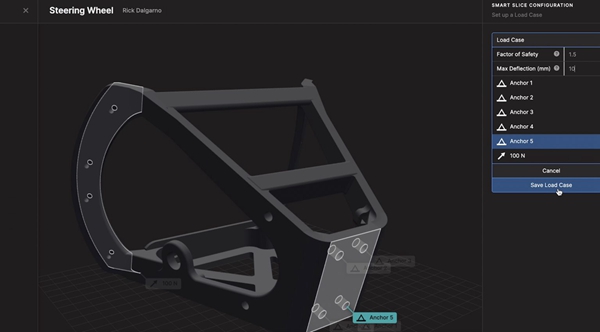

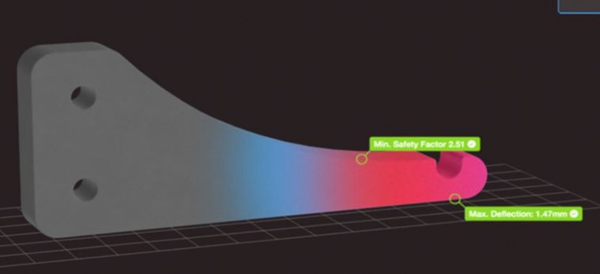

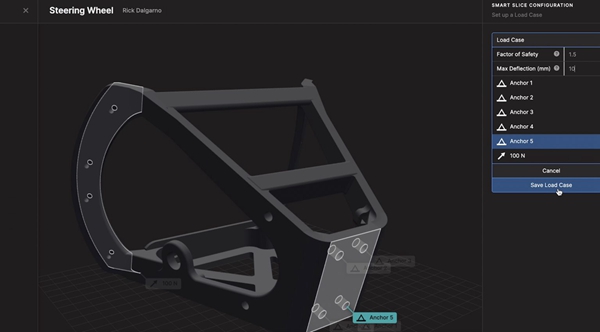

Simulation is easy to use so that different users can validate models before they are printed. Users can enter safety factors and loads to create the necessary support structures, materials and other settings for different parts of the part. Larsen Motorsports uses CCF (continuous carbon fiber) 3D printing to produce composite steering wheels that are customized for race car driver Josette Roach as an alternative to aluminum parts, and Brian Tocci, director of operations at Larsen Motorsports, said of the equipment. "We can now use simulation to test it, iterate on it and keep iterating on it until we get a design we're happy with. We don't have to print ten different parts, we can just do it all in simulation."

△ Racer Josette Roach holds her custom steering wheel, 3D printed using simulation and Simulation technology. Image courtesy of Markforged.

Simulation enables our customers to adopt The Digital Forge more deeply into their manufacturing operations by using validated and optimized models to predict the state of 3D printed advanced composite parts with continuous fiber reinforcement in advance," said Shai Terem, Markforged CEO. Software innovations like Simulation are central to our goal of bringing industrial part production to the point of demand."

What are the benefits of Simulation?

Markforged promises to provide a fast, automated way to verify part performance, ultimately making it fast and easy to print parts that are precisely optimized for the most demanding end-use applications. Simulation within the slicer means no more lengthy design-print-break test cycles, which are often expensive and time-consuming.

●Simulation allows users to ensure that 3D printed parts will have the strength required for industrial applications before printing. Powerful simulation technology optimized for additive manufacturing allows any user to simulate test parts to meet performance requirements without the guesswork of configuring print parameters.

●Simulation enables users to deliver trusted parts faster by reducing design-print-test iteration cycles and rework delays. Unlike traditional simulation tools that require specialized knowledge and time-consuming analysis, Simulation is integrated into Eiger (Markforged's software coming in 2019) and streamlined for additive manufacturing, so users can test parts in their familiar slicing and printing workflow.

●Simulation reduces the cost of 3D printed parts by automatically optimizing the amount of material and continuous fiber reinforcement required. Avoid overbuilding parts and wasting material by optimizing settings to meet user needs for strength, cost, and print speed. Replacing the traditional 5 to 25 iterations of trial and error printing experiments with simulation testing can save hundreds or even thousands of dollars per part. Ultimately, this can expand the use of fiber-reinforced composite parts, allowing more metal tools and end-use parts to be replaced faster, cheaper and easier.

Expanding Digital Manufacturing

Markforged is trying to extend its software further into the manufacturing floor with an expanded solution platform. This can be more profitable for the company as long-term software usage fees can generate ongoing revenue. As one of the primary software interfaces used by engineers on a daily basis, Markforged can make a big difference in the workflow. At the same time, Markforged's CCF 3D printing process is unique in that users do have to learn the technology in order to manufacture parts with the most qualified CCF.

Software is a key factor in the production process. If Markforged's software doesn't do a good job of helping people design for their printing process, the printer will become increasingly inconvenient to use. Certain processes, particularly metal powder bed fusion, are usually only available to a small number of people in a company. One person can produce millions of crowns and bridges through a semi-automated process with very little designer involvement. This is also true for many serial manufacturing applications. However, for tools used to solve problems on and off the shop floor, there needs to be a lot of people who can use it. If an employee needs to use a Markforged 3D printer, but doesn't know how to design for it, he will never actually use it.

Continuous carbon fibers are a widely used technology, and they can be used to reduce weight, make new parts that would otherwise be impossible, or completely redesign complex components. However, the software needs to be super easy and fast to learn so that everyone on the shop floor adopts it. In this case, Markforged's investment in software was not only a revenue-generating opportunity, but a necessary way to remove barriers to the flourishing of its technology.