SLM Solutions is certainly one of the leaders in the field of large-scale PBF powder bed fused metal 3D printing. According to Mohou.com, the company's newly released 12-laser-based NXG XII 600E 3D printer has a build volume of 600 x 600 x 1500mm, processes up to 1.5 meters in the Z-axis, and has received its first order from Concurrent Technologies Corporation (CTC), a major AFRL funded this work to bring additive manufacturing to advanced DoD applications.

Customers who have installed or will install the NXG XII 600 can take advantage of the scalable architecture with the option to upgrade the system to unlock the benefits of the extended Z build size. the NXG XII 600E is expected to be delivered on schedule in 2023. However, SLM Solutions' machine still partially lags behind some Chinese manufacturers in terms of processing size limits.

Eplus3D has developed a new nine-laser EP-M1250 metal 3D printing system with a build volume of 1258 x 1258 x 1350 mm.

The BLT-S1000, an ultra-large metal 3D printing machine from Platt, has increased the size of the forming chamber, with forming dimensions up to 1200mm x 600mm x 1500mm (excluding the 170mm thick substrate size), with 8 lasers as standard and optional 10 and 12 lasers, and the BLT-S1000 forming efficiency of 300cm3/h for the same part with 12 lasers.

△New NXG XII 600E

SLM Solutions has therefore decided to go further beyond the limits of manufacturing with its next groundbreaking solution, which once again changes the size of metal 3D printing. This breakthrough solution will be able to produce high-quality metal parts up to 3.0 x 1.2 x 1.2 meters in size (L x W x H), thus shaking up the industry. The large machine contains a core unit and a size-flexible build enclosure, allowing for the manufacture of components of all sizes. Combined with the advantages of SLM technology, the game changer offers users the possibility of perfectly customized production for individual needs.

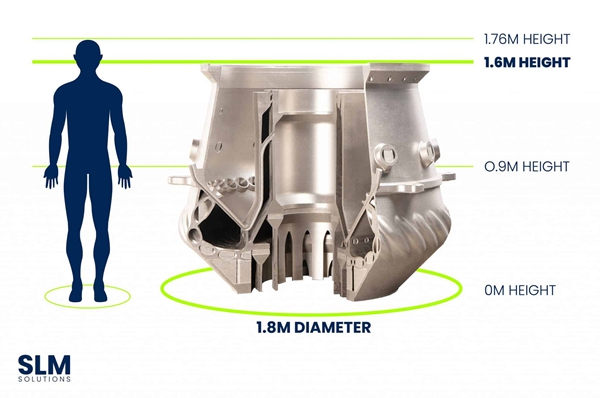

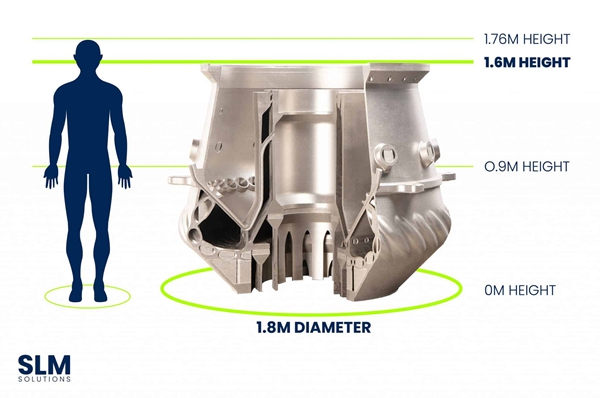

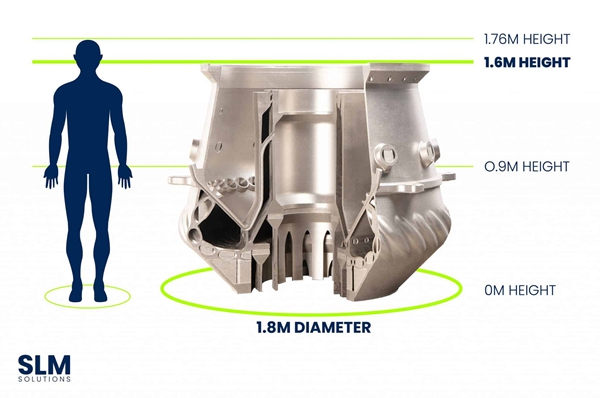

Additive manufacturing has often reached its limits when it comes to the size of the build chamber. Large parts are often impossible to build because they exceed the allowable installation space in the market. The flexible system solves this problem and will be a crazy boost to the whole additive manufacturing industry. For example, it allows the production of cylindrical parts up to 1.8 meters in diameter and 1.6 meters in height, or long parts with dimensions up to 3.0 x 1.2 x 1.2 meters. As a result, it can achieve manufacturing speeds of up to 330 cubic centimeters per hour.

△ Rocket motor nozzle expansion part, material: stainless steel, size: 1050 x 160 mm, print time: 160 h. Application: Aerospace

Sam O'Leary, CEO of SLM Solutions, explains: "This is another industry-changing technology that opens up new possibilities for transitional applications of additive manufacturing by removing geometric constraints. Each technology we develop is the result of an outstanding team effort, and they are solving our customers' manufacturing challenges and changing the future of manufacturing."

The new solution allows for the production of large metal parts for additive manufacturing; at the same time, it offers all the benefits of traditional SLM technology, such as design freedom or the reduction of multiple parts to one. In conclusion, Sam O'Leary commented, "It is not just a simple addition to the SLM solution machine portfolio. It is a true manufacturing revolution. We can't wait to show huge giant metal parts, it's almost unbelievable, but dare to challenge yourself."