August 9, 2022 - New Zealand artist Nicole Hone has developed a one-of-a-kind 4D printed artwork that is full of natural beauty and broadens the range of possibilities for multi-material printing, according to Mohou.com.

Hone is a3D printing research assistant at Victoria University of Wellington, New Zealand and graphic designer for the science-based green beauty brand Antipodes, working alongside her mentor, renowned industrial designer Ross Stevens. In Horn's latest collaboration with Stevens, they have designed and printed objects that can interact with natural elements such as water, air and ice, displaying them in a fascinating way. The piece is a visually stunning print that interacts elegantly with other elements without fuss.

This project is derived from MADE (Multi-Attribute Additive Manufacturing Design Experiment), a research strand at the University of Victoria's School of Design and Innovation that focuses on multi-material printing, also known as liquid printing research. It uses test software developed by Stratasys and materials from the J7 and J8 series of PolyJet 3D printers, part of a portfolio of products from this pioneering brand designed for high volume, high speed, multi-material printing for a variety of design and engineering applications.

For over a decade, MADE Research and Stratasys have been working to expand 3D printing technology through the development of new printer applications and materials. This collaboration recently made MADE part of an exclusive group of researchers with access to Stratasys' J7 and J8 printers. Then in 2021, Stratasys launched the PolyJet research package, which enables the printing of soft parts, hydraulic systems or fluid models with liquid support materials.

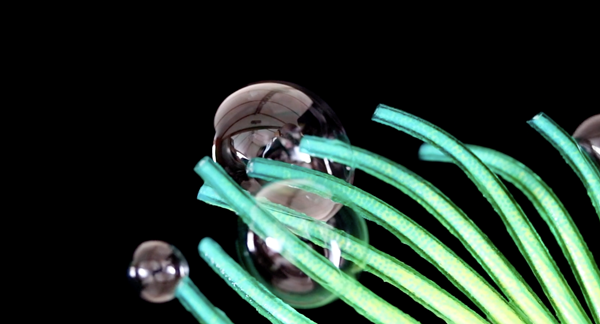

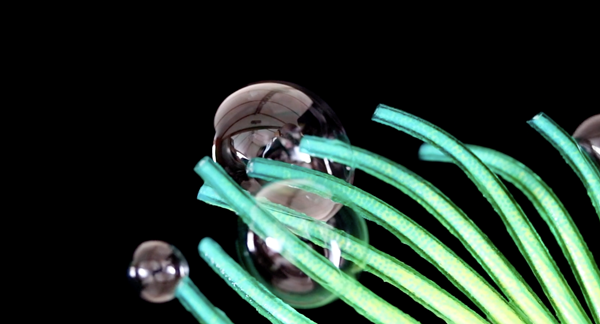

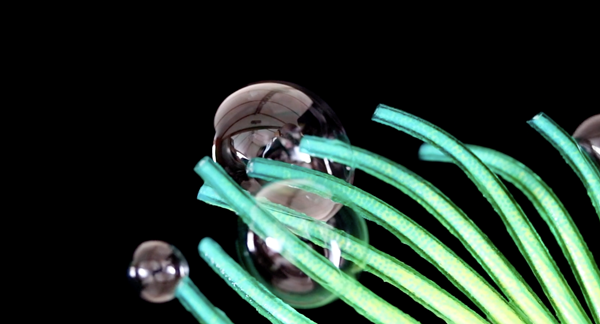

△NicoleHone and Ross Stevens' liquid printing project, here with the liquid four elements releasing bubbles. Image courtesy of Nicole Hone.

With these powerful printing systems, Stevens and Hone set out to design new objects for their 2022 project. First, the pair released three videos of the printed structures. The first, 'Liquid Four Elements', shows an algae-like 4D piece interacting with four elements (air, smoke, ice and water). Meanwhile, 'Liquid Leaves/LiquidLeaves' shows how a 4D printed leaf moves when a liquid element is inserted through a small tube. Finally, Polyphytes is a beautiful design that secretes various elements with a coordinated elegance that is unique to this project.

Made states on the Liquid Printing Project website, "Our main intention is to show how these simulated physical objects can create powerful visual effects without lengthy digital manipulation, in fact their simulated 'randomness' exceeds the digital creation potential in intricate detail."

As the process is still in the testing phase, the research team will not discuss how the structures were created. However, they did explain how the new software, printer and liquid support materials were able to print smaller, more reliable and complex internal pipes directly on the object.The liquid printing capabilities of PolyJet technology allow for the creation of these liquid-filled, airtight cavities inside the object. Previously, these cavities would have been filled with support material and would have been difficult to clean. The final structure is designed to allow for "multi-dimensional interaction with the actor or audience".

Hone published the results of her project in the July 2022 issue of Designboom magazine, focusing on the development process behind Polyphytes. In the published article, the designer explains that the basis of this work draws on the connection between 3D printed channels and the vascular system of natural plants. In addition, her research project film (shown below) explores the various physical effects produced when different substances flow through Polyphytes: water, air, smoke, icing sugar, foam mixtures and soap.

In her Designboom article, Hone explains: " Polyphytes are modelled programmatically in the design software Houdini with a series of internal channels, some as small as 1mm in diameter, and then printed on a Stratasys J850 using full-colour rigid photopolymer resin with varying degrees of opacity. The closed voids were initially filled with PolyJet cleaning fluid and then evacuated in post-production, which allowed the channels to become instantly free-flowing."

The designers say that while the research is focused on filmmaking applications of the new material, its potential could easily be extended to medical and other creative uses. Victoria University and Ross Stevens have a history of working with film research, and Stevens even led a project at the School of Design where he explored 3D and 4D printing for film and coined the term computer-generated imagery (CGI), which is the use of computer graphics to create images in a wide range of niches, including film and computer animation.

△ Nicole Hone and Ross Stevens' liquid printing project, here with succulents releasing water. Image courtesy of Nicole Hone.

While CGI was still a novelty when Stevens came up with the Lissom project in 2015 (seeing 3D printed objects interact with humans in real life and display the characteristics of living organisms), 3D printing enthusiasts are already looking at new developments. One of these was Object Reality (OR), a new term he developed to describe digital objects taken out of the virtual world and given life in the physical world, thus expanding the world of digital creation.

Stevens, Horn and other postgraduate students from the School of Design have been heavily involved in projects for New Zealand-based special effects and props company Weta Workshop. Much of the work done at Victoria University has already provided an excellent basis for projects for the award-winning company. Students have even found work helping to create special effects for many well-loved shows and films.