Researchers at the University of the Basque Country in Spain have developed a 3D printingtechnology that can be used to personalise medical and on-demand drug tablets. The main objective of this work is to produce 3D printed starch-based tablets for the customised delivery of hydrophobic drugs. The results of the research were published in the recent International Journal of Pharmacy.

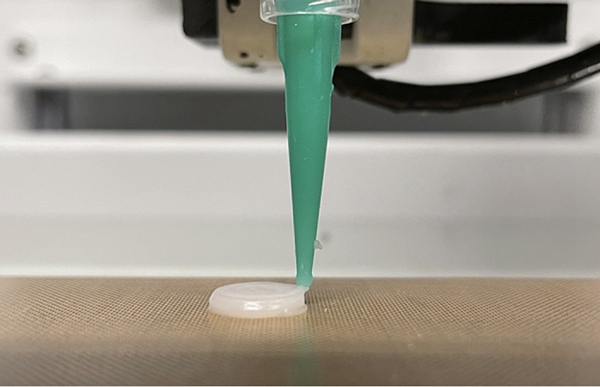

Image credit: University of the Basque Country, Spain

Conventional methods produce drugs with specific parameters that in many cases do not meet the individual needs of patients. In fact, conventional drugs are often based on adult doses, while paediatric and elderly patients need doses tailored to their age. What's more, certain patient groups also require specific dosage form alternatives to make the drugs easier to take orally. In this regard, fast-disintegrating tablets are emerging as a good option, as they dissolve as soon as they are placed on the tongue. Another challenge that pharmaceutical companies need to address is controlling the release of drugs over time.

3D printing is a technique for printing products layer by layer, in which materials are deposited layer by layer according to a digital model designed by computer design software. Using a fast, simple method and with the aid of 3D printing, the researchers prepared tablets based on three starches: two corn starches (normal and waxy) and a potato starch, all with different geometries and loaded with insoluble drugs.

Before the materials used could be injected into the printer, the researchers explained, it was necessary to ensure that the materials were printable and that they would retain their shape once printed. To do this, a detailed rheological analysis had to be carried out. All three types of starch showed appropriate rheological properties, although in the case of potato starch, the printing process became more laborious due to its properties.

The researchers observed that the plant origin of the starch was crucial in almost all properties, such as porous microstructure, formation of stable networks or drug release. In the case of regular maize starch, drug release was instantaneous, with the drug being fully released within 10 minutes; in the case of waxy maize starch and potato starch, release was more continuous and could take up to six hours to be fully released. The researchers also demonstrated the importance of tablet geometry in drug release.

The research team also printed tablets combining different types of starch. In this case, the release took place in two stages. For example, in the case of an infection, the drug is released immediately for pain relief in the initial phase with the normal corn starch, and more consistently in the subsequent phase with either of the other two starches.