Sept. 25, 2022 - Oxford Performance Materials (OPM), a U.S. leader in advanced polymer science, 3D printed orthopedic devices and coating technologies, is assisting the Orthopedics Department of Ukraine (OHFU) by manufacturing and delivering 3D printedcustom implants, as well as suture anchors and sets of instruments, to treat injured personnel in Ukraine.

OPM is treating injured personnel in Ukraine through the manufacture and delivery of 3D printed custom implants and suture anchors.

About OHFU

It is a non-profit organization established to meet the orthopedic and surgical needs of Ukrainian hospitals. Currently, Ukrainian orthopedics is receiving a large number of patients suffering from severe bone defects due to war trauma. Many of these injuries involve complex bone reconstruction and require technical solutions that are faster than conventional treatments, as well as materials with appropriate biocompatibility and purity. These 3D printed implants, which can be used for traumatic injuries, have been shown to integrate well with bone and have antimicrobial properties to control infection.

Janine Ignatenko, executive director of OHFU, said: "A key part of OHFU's mission is to identify new technologies and capabilities to explore a way to rapidly treat, as a result of war, complex bone defects that result in very high rates of amputation. Currently, there are limited partner technologies that can meet the specific collaborative needs of our institution."

He continued, "In the meantime, we have been looking at and researching 3D printed implant technology as a potential solution. After reviewing a series of articles and peer-reviewed studies, we contacted OPM, the world's only supplier of biomedical 3D printed PEKK polymer implants, a company with a track record of providing successful treatments for complex, specific patients."

OPM has a proven track record of providing 3D printed bone implants for complex, specific patients

OPM's suture anchor solution is perfect for our situation, one that provides bone growth, inherent antimicrobial properties and a relatively low unit cost," said Janine Ignatenko. In addition, OPM's instrumentation suite is sterilizable and reusable, which is a significant benefit to our hospital partners."

He continued, "OPM has shipped our first suture anchors and therapeutic instruments at no cost and has initiated a specific 3D printed implant protocol for the first patient. opm is committed to providing OHFU surgeons, on an ongoing basis, with 3D printed implants at no cost. However, the need is great and we want to engage everyone and any organization that can afford it to support our foundation. Finally, we recognize the uniqueness of ongoing clinical experience and in return, we will provide clinically relevant data to support surgeons and patients in future global conflicts."

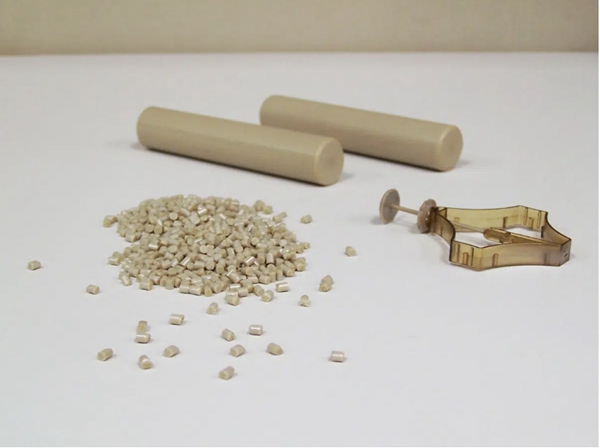

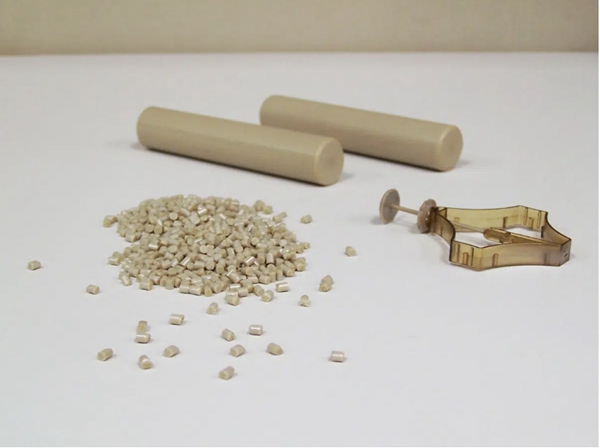

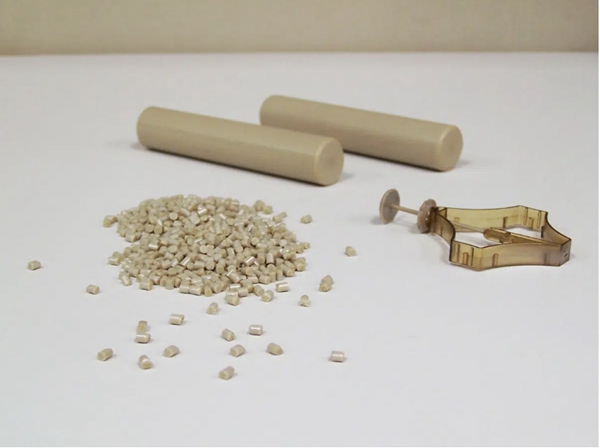

△High performance PEKK material developed by OPM with a very wide range of applications

About OPM

Since 1999, Oxford Materials has been developing advanced applications and proprietary manufacturing processes for PEKK materials for biomedical, aerospace, and industrial products. in February 2013, OPM became the first company to receive FDA approval for the production of 3D printed polymer implants at that time, and in July 2014 OPM, once again, received FDA approval for the production of, for specific patient-specific facial implants

The company has applied its success story to a large number of high-performance polymers for the aerospace, industrial and biomedical markets. With the latter, OPM has in recent years developed its highly innovative OsteoFab technology, which entails the manufacture of polyetherketone (PEKK) powders in 3D by selective laser sintering (SLS). Using this specialized process, OPM has the ability to 3D print orthopedic and neurological implants with properties such as radiographic capability, bone-like mechanical properties and unique textured surface topography.