The foot and ankle surgery department of a hospital in Yantai completed a personalized 3D printed prosthesis for partial ankle replacement, successfully relieving the patient's pain

Recently, Mohou.com understands that the foot and ankle surgery department of a hospital in Yantai completed a personalized 3D printedprosthetic ankle partial replacement, which successfully relieved the patient's pain. The application of this technology brings a new hope of preserving joint function for patients with old Pilon fracture deformity healing.

△Doctors are performing surgery on the patient

Mr. Wang, 29, fell and injured his right ankle 11 months ago, causing an intra-articular occult fracture. After receiving conservative treatment for several months, he gradually developed ankle walking pain, which seriously affected his daily activities. After careful examination, Qu Wenqing, director of foot and ankle surgery of Yantai Mountain Hospital, diagnosed him with old Pilon fracture deformity healing and ankle traumatic arthritis, CT and MRI showed widening of the lower end of the tibia, partial collapse of the articular surface of the tibial dome up to 8 mm, and cartilage defect of the talus, which was caused by severe tibio-talar joint mismatch and cartilage wear. The patient felt severe pain. After listening to Director Qu's introduction, the patient was deeply worried about his condition and was looking forward to treatment with great anticipation and anxiety.

After many inquiries, Mr. Wang finally chose to undergo surgery at Yantai Mountain Hospital. After detailed evaluation, the foot and ankle surgery team finally decided to perform 3D printed prosthetic ankle partial replacement for him in order to preserve his ankle function to the maximum extent.

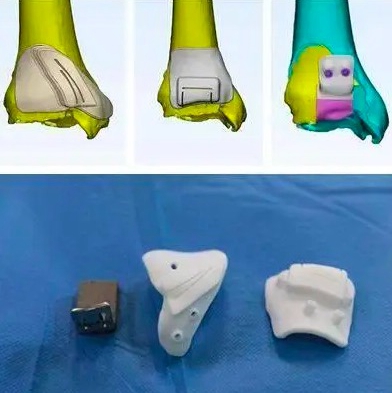

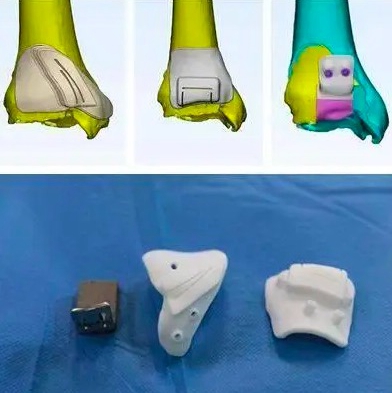

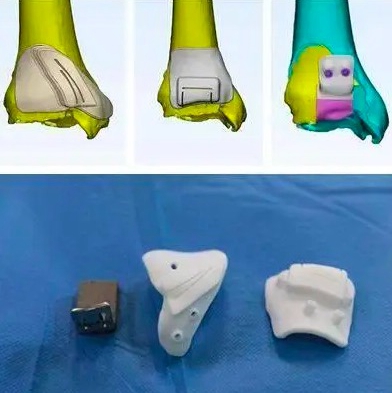

It is reported that this is a personalized 3D printed prosthetic ankle joint partial replacement in Shandong Province, and there is little domestic experience to learn from. Vice President of Yantai Mountain Hospital Chang Liming and Director of Foot and Ankle Surgery Qu Wenqing paid great attention to the patient and made a detailed preoperative preparation and a personalized surgical plan. Qu Wenqing and the R&D team of 3D printing center held more than ten technical discussions, drew dozens of line drawings, designed special osteotomy guides for the tibial dome and collapsed joint surface with significantly widened anterior and posterior diameters, and designed individualized distal tibial metal prosthesis and polyethylene liner according to the healthy side of the ankle joint through the mirror flip technology. The precise and detailed preoperative design provided a guarantee for the surgery. During the surgery, through the precise guidance of the osteotomy guide, the multi-planar osteotomy of the distal tibia restored the normal width of the anterior and posterior diameters of the dome, removed the damaged and collapsed cartilage and fragmented bone, and preserved the normal articular surface of the tibia to the greatest extent. The surgical team successfully completed the partial replacement of the right ankle joint in 2 hours. After the surgery, the joint recovered a good match and the patient was successfully discharged from the hospital recently.

3D printed osteotomy guide and metal prosthesis

Qu Wenqing said, in the past, when facing the deformity healing of old Pilon fracture, most of them used osteotomy and ankle fusion, considering that the patient was young and part of the joint surface was still flat, osteotomy and orthopedics alone could not effectively delay the development of traumatic arthritis, and the postoperative effect was not exact. After the fusion, the patient's joint function was completely lost, which seriously affected his daily life. Total ankle arthroplasty is a mature technology, and the foot and ankle surgery department of Yantai Mountain Hospital has carried out the replacement independently two years ago, which can retain a certain degree of joint mobility, but for this young patient, it is more traumatic, with more bone loss and a high possibility of secondary revision later. In this case, the unique advantage of 3D printed prosthetic ankle partial replacement was that the osteotomy guide and distal tibial prosthesis were tailored to the patient's fracture characteristics, which preserved ankle mobility with less trauma, maximized bone volume, and protected the adjacent joints from secondary arthritis due to increased pressure in the adjacent joints, which could significantly improve the patient's quality of life.

The successful 3D printed prosthetic ankle joint partial replacement by the foot and ankle surgery department of Yantai Mountain Hospital fills the gap in this technology in the province. It is reported that the Medical 3D Printing Innovation Research Center of Yantai Mountain Hospital is a medical 3D printing innovation research center in Yantai, which was jointly founded by Yantai Mountain Hospital and the Clinical Translation R&D Center of 3D Printing Technology of the Ninth People's Hospital of Shanghai Jiaotong University School of Medicine in October 2021. The center has experimental sites such as 3D guide plate and model printing laboratory, endophytic prosthesis laboratory, etc. It mainly uses computer digital technology to assist in surgical planning and clinical application of 3D printing technology by researching medical imaging, processing, modeling, and augmented reality technology, with new scientific concepts, solid theoretical foundation, and advanced treatment mode to achieve more accurate diagnosis and treatment in clinical medicine widely used. Yantai Mountain Hospital 3D printing innovation research center has been adhering to the concept of "scientific and technological innovation, people-oriented", and with the strong support of academician Dai Kerong of Shanghai Jiuyuan Hospital and Binzhou Medical College, it has been increasing the investment in scientific research to benefit patients with more scientific research achievements.