A group of researchers at the University of Halle-Wittenberg (MLU) in Germany is working on a more convenient means of repelling mosquitoes, using 3D printing technology to create mosquito repellent rings or arbitrary wearables.

Oct. 13, 2022 - A group of researchers at the University of Halle-Wittenberg (MLU) in Germany is working on a more convenient means of repelling mosquitoes by using 3D printing technology to create mosquito repellent rings or arbitrary wearables. The researchers developed their prototype product using a common insect repellent called IR3535.

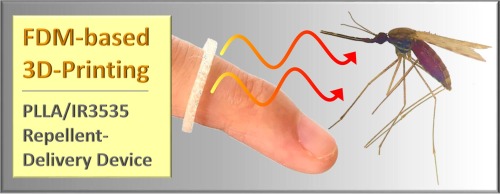

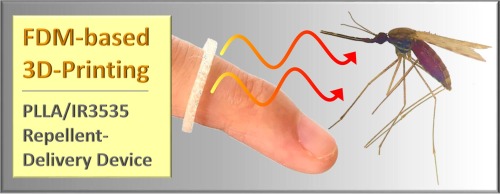

△ Scientists have developed a new 3D-printed wearable ring designed to repel mosquitoes and other insects over time

In Africa, a child dies of malaria every two minutes. Mosquitoes and humans are in a war. To help humans win, scientists are working on new strategies. IR3535, also known as repellent (ethyl butyl levulinate), is a broad-spectrum, highly effective insect repellent. It has good repellent effect on flies, lice, ants, mosquitoes, cockroaches, midges, gadflies, flat fleas, sand fleas, sand midges, whiteflies and cicadas, and can be used under different climatic conditions.

△ Some mosquitoes, by transmitting the blood of malaria patients to normal people, cause the disease

Traditionally, it is usually used as a spray or lotion and provides protection for several hours. However, Androsch and his team were looking for a more portable way to release the chemical slowly and continuously over a longer period of time, for example by encapsulating it in a wearable ring or bracelet.

△ Using IR3535 and 3D printed polymers to create a convenient, fast and long-lasting means of repelling insects

Using 3D printing technology to gain innovation

The IR3535 active ingredient is first "encapsulated" and formed into a desired shape, such as a ring or any easily wearable shape, and then the repellent can be worn and released. In such a system, a solid polymer carries a liquid repellent that can be slowly released into the environment. As a new approach, the team says the 3D printed polymer solid repellent, repels insects beyond similar devices previously developed by different technologies. says MLU's Professor Rene Androsch: "Insect repellent sprays containing IR3535 are very gentle on the skin and have been used around the world for many years. This is why we have been using the chemical in our experiments." The team used a special 3D printing technique that allows them to print 3D parts containing up to 25 m% repellent content and with minimal loss of repellent during the printing process, inserting the repellent into biodegradable polymers and shaping the substance mixture in various ways in a controlled manner.

The team's research has been published in the International Journal of Pharmacy under the title "3D printing of polymer/repellent system poly(l-lactic acid)/ethyl butyl levulinate (PLLA/IR3535)" (Portal)

Core highlights of 3D printed mosquito repellent ring or bracelet

*Polymer/insect repellent PLLA/IR3535, which can be 3D printed to obtain a drug delivery device.

*Maximum insect repellent load of 25 m% achieved.

*The evaporation rate of IR3535 at normal body temperature can last at least 5-10 days.

The lead author of the study, MLU PhD student Fanfan Du, said, "The basic idea of 3D printing insect repellent rings is to slow down the evaporation of the repellent ground and effectively form a repellent barrier; the rate of repellent evaporation depends on many different factors, including temperature, concentration and the structure of the polymer used." After conducting various experiments and simulations, the team predicted that it would take more than a week for the repellent to fully evaporate at a body temperature of 37 degrees Celsius. For samples containing small amounts of Roundup, the crystallization of PLLA was inhibited by a fairly rapid cooling step and a bed temperature of about 25 °C, which is below the glass transition temperature of homogeneous polymers or Roundup. At higher repellent concentrations, the crystallinity increases slowly during post-printing storage as the glass transition temperature decreases to near or even below ambient temperature. For all samples, the rate of repellent release increases with temperature regardless of the initial repellent concentration and has a release time constant of approximately 10 days at ambient temperature. While researchers have demonstrated that it is absolutely possible to develop a wearable insect repellent, the rings and other forms created for the study are currently nearly prototype designs.

Although some of the diseases caused by mosquito bites in our country are now very rare, there is still a very promising market in the future for African countries to use 3D printing technology to introduce such a convenient, fast and environmentally friendly insect repellent technology. The researcher said further research is needed to determine how the ring functions under real-world conditions.