Introduction: Plastics are tough cut versatile materials, they are great when they are used, but not so friendly when they end up in the environment.

28 June 2022, EPFL scientists have now developed a new PET-like plastic material that comes from waste plant matter and can be chemically recycled or degraded in the environment to harmless sugars. This new material derives its strength from lignin comparable to that of plastic. Lignin is a biopolymer that forms the hard walls of plant cells. In previous research work, the EPFL team developed a method for cooking non-edible plant materials such as wood and bark in cheap chemicals, which extracts and stabilises lignin to produce a plastic precursor material. Now, in the new study, the researchers have used a different but related chemical to create a more versatile bioplastic.

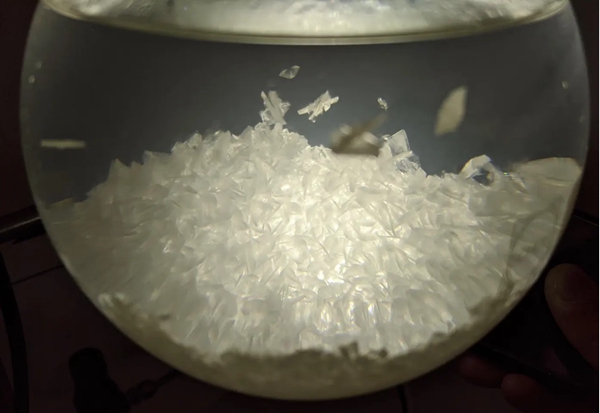

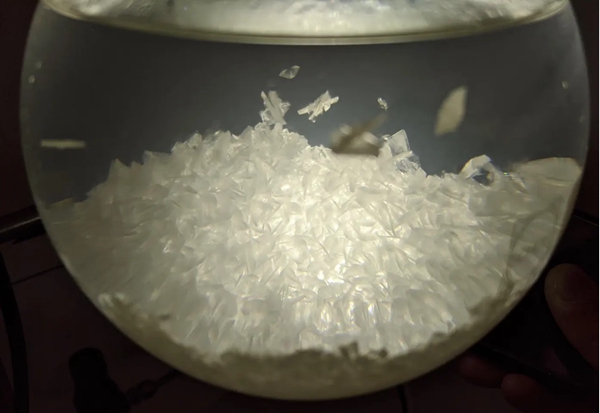

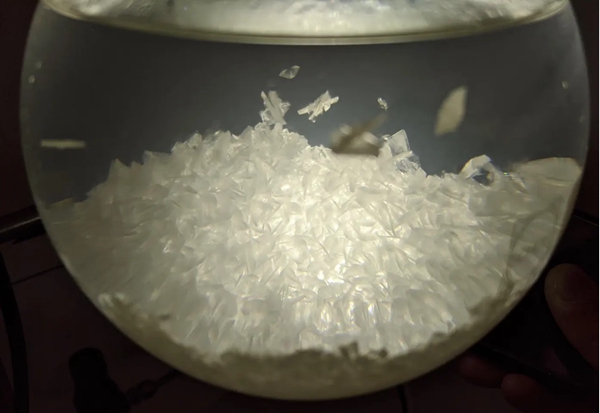

(a) schematic diagram of natural wood composition; (b) optical photograph of lignin 3D printed honeycomb structures; (c) photograph of lignin particles and direct lignin-based ink printing; (d) radar plot of the performance of 3D structures prepared by the FDM method compared to direct ink printing; (e) radar plot of the performance of 3D structures prepared by cellulose compared to lignin.

By using a different aldehyde - acetaldehyde rather than formaldehyde - we can simply sandwich 'sticky' groups on either side of the sugar molecule and then enable them to function as plastic building blocks," said Lorenz Manker, first author of the paper on the study. By using this simple technique, we can convert up to 25 per cent by weight of agricultural waste or 95 per cent of purified sugar into plastic."

The resulting bioplastic shows many of the desirable properties of conventional plastics. It can withstand temperatures of up to 100°C, has a tensile strength of up to 77 MPa and a hardness of up to 2,500 MPa, plus it forms a strong barrier to oxygen and water vapour. It is also very versatile, with the research team demonstrating that it can be used to make packaging film, 3D printed filaments or fibres that can be spun into textiles. The environmental friendliness of this material is not limited to its creation - its disposal is also green. It can be chemically recycled using the same process currently used to recycle PET plastic and if it does enter the environment then it will degrade to its constituent plant sugars rather than microplastics.

There are a number of plant-based bioplastics currently in development and major companies such as Lego and Coca-Cola are already trialling them in their products. As with all such advances, there are still some hurdles to overcome before they can be scaled up to mass production, but in this case the team says the chemistry to make the new bioplastic is simpler than others and it uses cheap, already widely used chemicals.

The plastic has very exciting properties, particularly in applications such as food packaging," said Jeremy Luterbacher, first author of the paper on the study. What makes this plastic unique is the presence of a complete sugar structure. This makes it very easy to manufacture because you don't have to modify what nature gives you, and degradation is also simple because it can go back to molecules that are already abundant in nature."