Cosmic Grips ("CG") is an American rock climbing point manufacturing company founded in 2020. As a small startup, it was not cost effective to manufacture small orders of climbing points by traditional production methods, given the scale of production. In addition, product quality cannot be guaranteed. Complex design requirements such as: die pulling slope and tool setting accuracy make it difficult to process the ideal shape with traditional processes, and hand production cannot guarantee quality stability for small batch production ...... How should these problems be solved? How can we achieve high quality and efficient small batch production?

In order to balance cost efficiency and production quality, the two founders who have been pursuing digital production finally decided to introduce3D printing technology for small batch production.

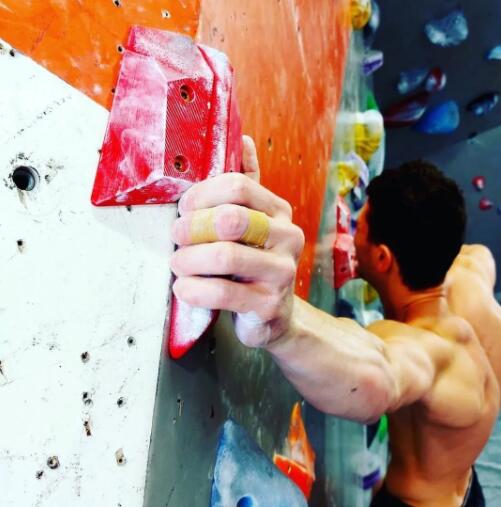

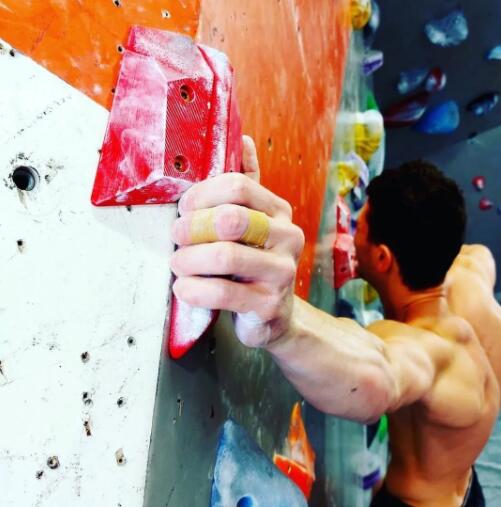

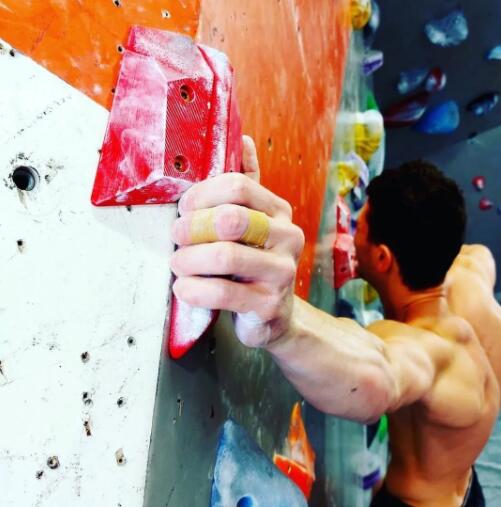

Climbers using CG products © Cosmic Grips

High-precision and flexible production

Balancing design aesthetics and mechanical performance

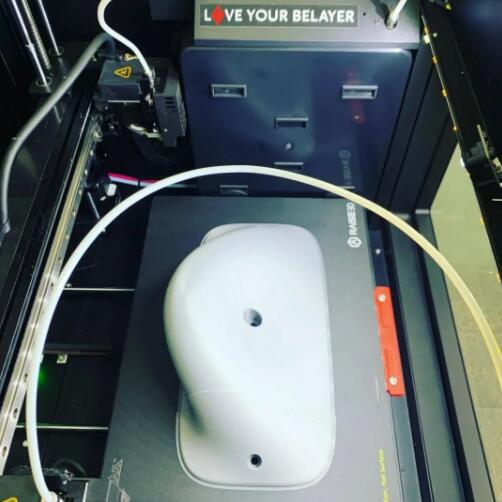

After evaluating their printing needs and comparing the performance of various 3D printers, Cosmic Grips chose the Raise3D-Shanghai Fuzhi E2 3D printer as the manufacturing tool to produce artistic and lightweight rock climbing points. The Raise3D E2's strength lies in its high printing accuracy and stable printing performance, which can accurately print high quality models and ensure a smooth and fine surface for the rock climbing points. As a flexible production model based on 3D printing, E2 can also easily achieve complex structures that cannot be machined by traditional processes, which gives designers the freedom to design products while still ensuring high quality production and a good interface between design aesthetics and mechanical optimization.

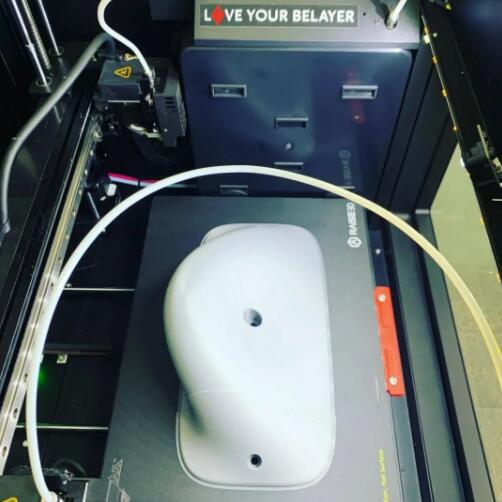

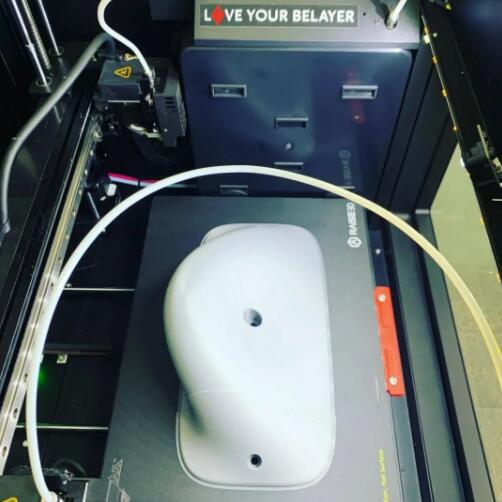

Climbing point product produced with Raise3D E2 3D printer © Cosmic Grips

Stable operation and easy maintenance

All-day production with peace of mind

As a startup company, CG has limited production and management staff, and the question of how to use limited labor to achieve efficient production has always been a problem for CG. Therefore, when purchasing 3D printers, CG pays more attention to the stability and ease of operation of the machines. Since the introduction of Raise3D E2 for production, even if there is a power outage, the printing task can be continued after the power is restored, solving the problem of printing interruption due to power outage and material breakage.

3D printed rock climbing point © Cosmic Grips

The two Raise3D E2 printers that CG initially purchased have been running 24/7 since they went into production, completing small batches of more than 60 product lines in two years, ensuring production of rock climbing points and other models to meet self-production and Vertical Solutions' supply needs.

Digital production

Enabling efficient small batch production

In the future, more and more niche markets will need to use 3D printers to break through the bottlenecks encountered in small production runs and to achieve commercial transformation. Raise3D's high precision and stable operation of 3D printing solutions will also be a solid guarantee for customers.

Founder NIR Beit-Av in the studio © Cosmic Grips

As Nir Beit-Av, one of the founders of CG, says: "CG has achieved an efficient and precise commercial transformation with the production method of 3D printing. Since we bought it 2 years ago, our Raise3D E2 has been running 24/7, never stopping, and it gives us great peace of mind that we don't need to take care of it or worry about production interruptions due to power or material outages, and most importantly, the E2's print quality is consistent and excellent, which we all particularly like. In addition, the price of E2 is also very suitable as a production tool, and we have purchased more Raise3D machines to expand our production after the demand of orders increased."